Ethanol producer automates acoustic valve leak detection for molecular/mole sieve system

- Inspected 16 valves on molecular/mole sieve system and identified 3 through-valve leaks

- Delivered same-day inspection results and repair guidance

- Saved $3.5M annually on energy costs through product loss avoidance

Challenge

Process industries frequently struggle with hidden valve leaks that disrupt production and increase costs. These leaks occur when valves that are supposed to be fully closed allow fluid to pass through, often silently and invisibly. In critical applications like ethanol production, internal valve leaks can lead to recycled processing, pressure instability, increased energy costs, and significant product loss.

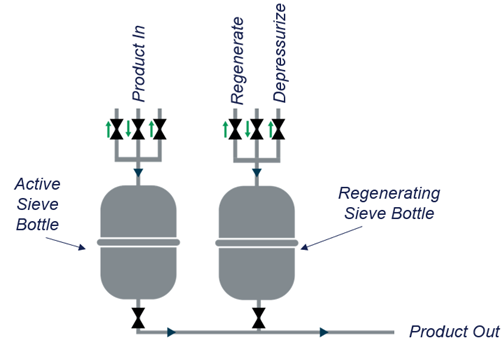

This was the case at an Iowa-based ethanol facility, where operators were facing recurring efficiency issues due to valve leakage within their molecular/mole sieve system, the final step in the distillation process. Without a reliable way to identify which sieve valves were leaking, the team relied on antiquated methods including manual inspections, educated guesses, and blind valve replacements. This approach often involved taking the distillation system offline, cooling it down, swapping out valves, and hoping the issue was resolved—resulting in extended downtime, wasted labor, morale issues, and unnecessary costs.

Solution

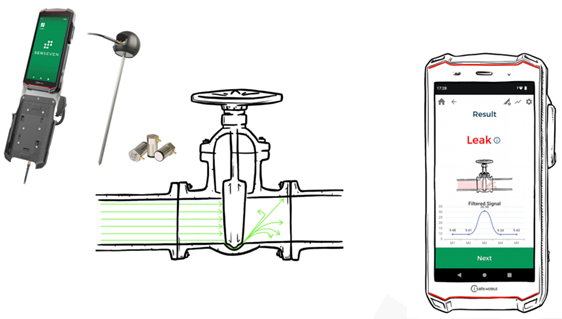

The facility engaged Midwest Valve Services to conduct a digital valve inspection using a Senseven handheld acoustic detection device. This non-invasive technology detects high-frequency sound waves emitted by fluid leaking inside closed valves, helping identify and quantify internal leaks with 95% accuracy, far surpassing antiquated methods that are only accurate 60% of the time.

Midwest Valve Services technicians completed a guided inspection across 16 valves in the molecular/mole sieve system using a three-point contact method (inlet, outlet, and valve body) to measure and collect acoustic data. Using mobile, cloud-based software, Midwest Valve Services analyzed the signals to precisely identify leaking valves and delivered a detailed inspection report, complete with leak severity, valve identification, and maintenance recommendations to the facility the same day.

Outcome

The inspection report identified three leaking valves within the molecular/mole sieve system, each contributing to significant product loss and energy waste. These internal leaks caused ethanol to recycle through the distillation process, consuming excess electricity and natural gas, and reducing overall throughput. In fact, the facility was losing up to 5% of its production capacity, with an estimated economic impact of $3.5 million annually.

By identifying the exact valves responsible, the facility avoided unnecessary replacements and was able to schedule targeted repairs during planned downtime. This eliminated the need for blind valve swaps, emergency call-ins, and extended outages. Technicians were prepared in advance, parts were ordered with confidence, and only the necessary valves were replaced, enabling the molecular/mole sieve unit to operate at peak performance.

The leak detection and valve repair scope yielded an ROI of just 2-3 weeks, making it a highly cost-effective maintenance decision. The success led the plant to adopt Midwest Valve Services’ digital valve testing as part of its annual pre-outage maintenance strategy, with plans to expand the service across other critical systems.

Stop guessing. Start saving. Partner with Midwest Valve Services to uncover hidden valve issues, reduce downtime, and protect your bottom line.

Each molecular sieve vessel (or “bottle”) typically has four isolation valves that control the flow of vapor and liquid during the dehydration cycle. These valves must seal tightly to prevent ethanol from leaking through and being recycled back into the system. If a valve leaks internally, the ethanol bypasses the sieve and re-enters the distillation process, consuming additional energy and reducing throughput.

The device features a three-point contact method (inlet, outlet, and valve body) to measure leak severity and location. It’s Class 1, Div 1 explosion-proof, making it safe for use in hazardous environments. Reports are generated in compliance with ISO 18081 and can be exported to maintenance systems for streamlined planning.