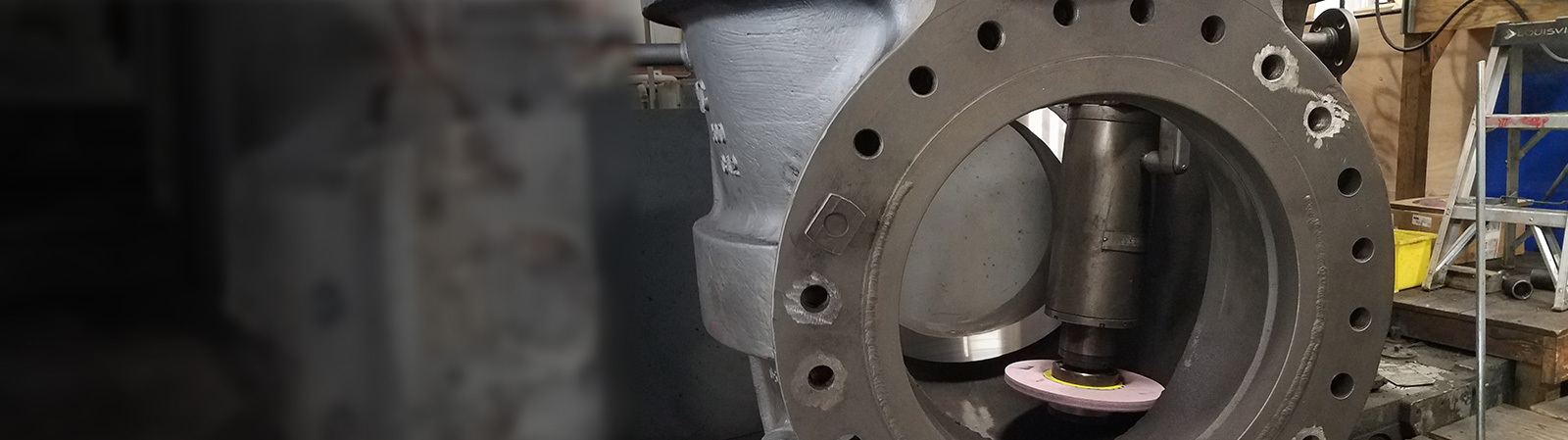

Upgrades & Modifications

Enhance Performance and Improve Reliability.

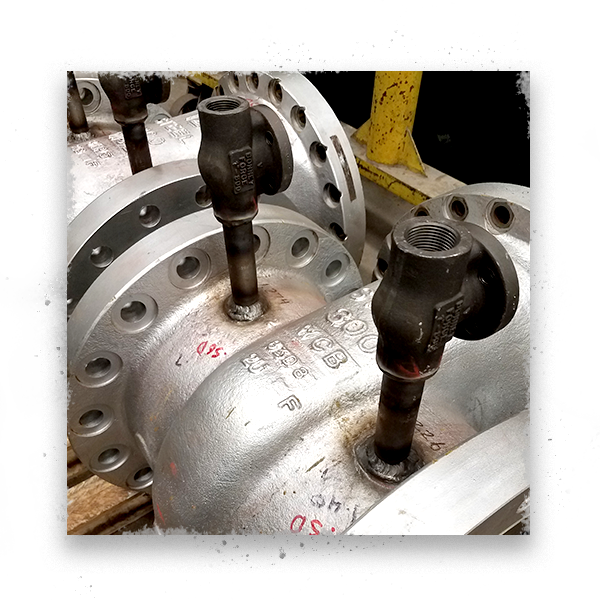

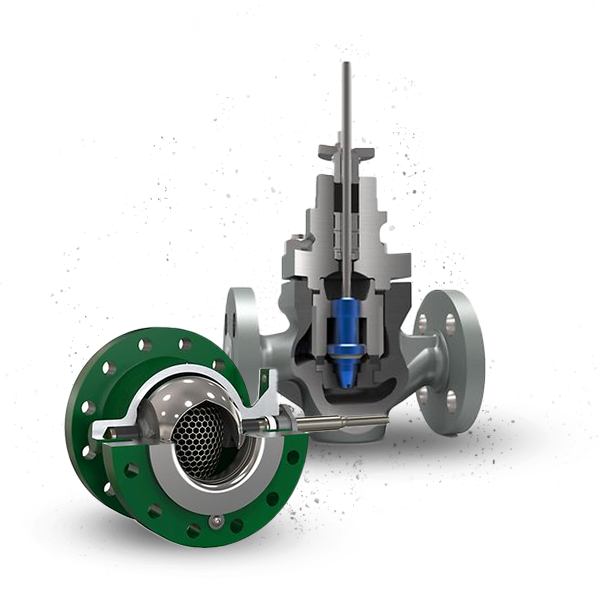

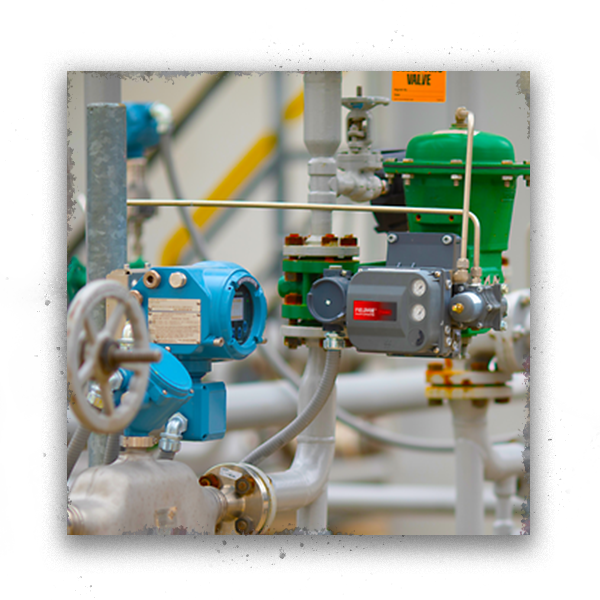

In addition to major repairs, we can make upgrade and modification recommendations that will enhance performance and improve efficiency. Typical upgrades, modifications, and other services that can extend the life of your valves include: